ABSTRACT

Codelco is a state-owned Chilean mining company that is the largest copper producer in the world. Its innovation strategy involves transferring and adapting existing technologies and developing new ones to address the challenges confronting the company’s mining and processing operations. Codelco focuses on developing and applying smart mining technologies through every stage of the mining cycle. This approach is helping Codelco improve productivity, operational efficiency, and to ensure a significant impact to cost savings. This case study outlines the application of HARD-LINE’s TeleOp control systems on several heavy-duty machines at Codelco’s Mina Sur Mine.

INTRODUCTION

The pilot project was conducted at Codelco’s Mina Sur, 1,400 km north of Santiago (near Calama). Codelco has other operations in the area, Chuquicamata and Radomiro Tomic, mining primarily high volumes of low-grade copper. Members of the head office put together a pilot project to mine 52 m banks (Talud-Vertical). The strategy reduced the amount of overburden to be excavated and allowed workers to go down to greater depths in the open pit.

Codelco decided to implement HARD-LINE’s Teleop systems as a solution for its pilot project. The trade-off between achieving a bigger bench and handling less overburden versus the risk of losing a machine proved to be feasible. HARD-LINE’s Teleop technology allowed the operators to safely complete this aggressive technique without any risk to human life.

APPLICATION

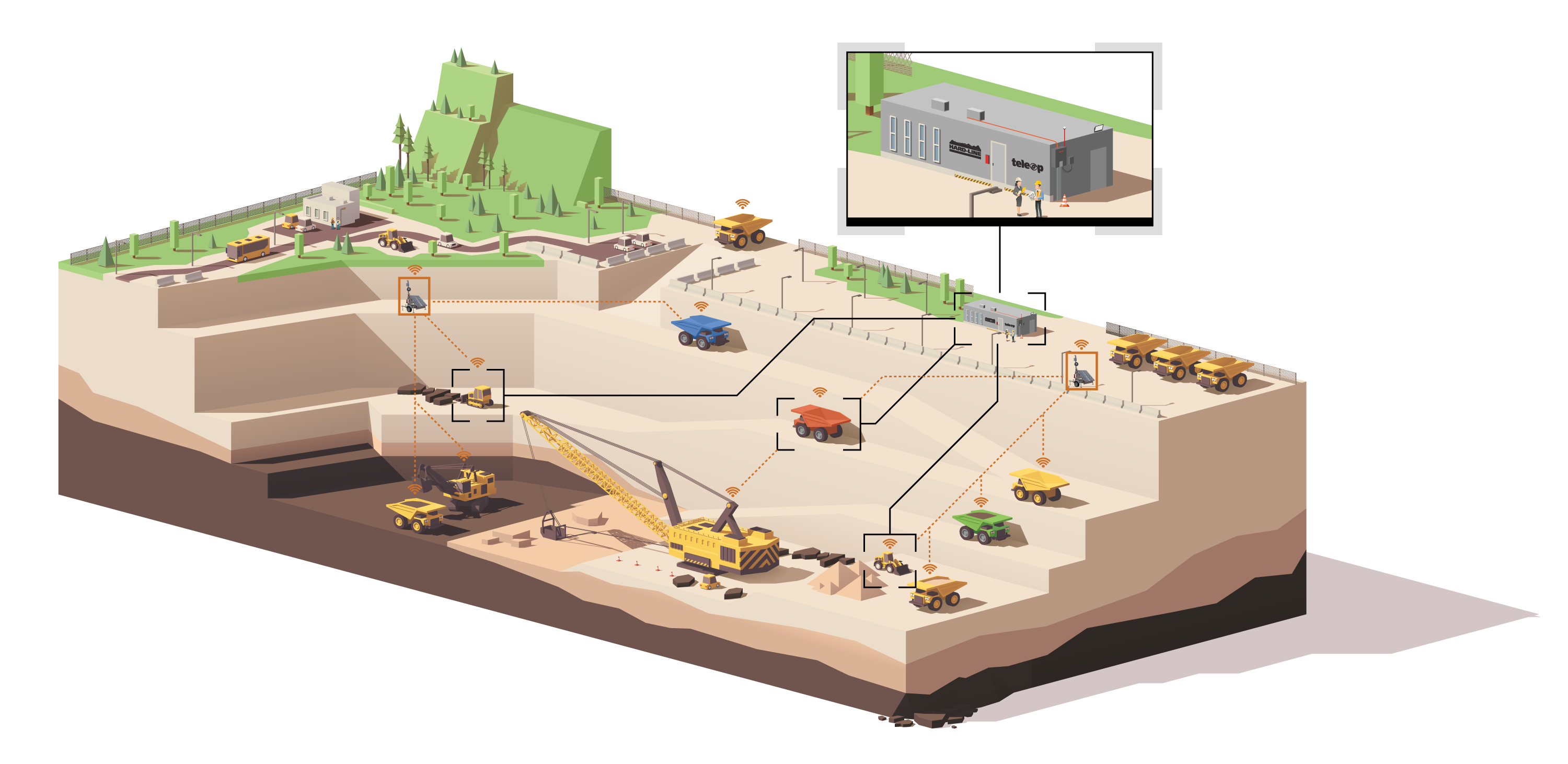

Codelco purchased seven Teleop systems to operate multiple heavy-duty machines at Mina Sur. The systems remotely operated three haul trucks (Komatsu 830E-AC), two dozers (Komatsu D375A and Caterpillar 834H), one shovel (Komatsu PC5500-6), and one water truck (Komatsu HD785-5LC) in the open pit. HARD-LINE’s non-proprietary network was installed on-site with access points to connect the machines to the Teleop systems via WiFi. The Teleop control systems were installed in a control room approximately 2 km away non line of sight, providing a safe and environmentally friendly location for the operators (as shown in figure 2). The systems addressed Codelco’s safety concerns surrounding the pilot project. Each operator station was customized to function as if the operators were inside the vehicles using the actual equipment. This action reduced the amount of training required for the operators.

CONCLUSION

The key to smart mining involves innovative strategies. The focus is on maximizing production efficiency and enhancing safety measures by implementing smart mining technologies at every stage of the mining cycle. These gains are shown to the company’s bottom line. HARD-LINE produces a diverse and flexible range of technology, from radio remote controls to tele-remote systems and automation packages customized to suit the needs of any customer, regardless of the make, model, or year of the machines. HARD-LINE’s technology improves efficiencies, enhances safety, and increases the profits of mines all over the world. For Codelco’s Mina Sur Mine, HARD-LINE offered a safe solution for the pilot project. HARD-LINE’s Teleop control systems removed the operators from the hazardous environment that surrounded the project. The proof of concept was successful and delivered by HARD-LINE’s TeleOp technology.

Disclaimer: The heavy machinery used in this project are products and creations of Komatsu and Caterpillar.

Figure 1. Open pit mine 1,400 km north of Santiago (near Calama).

Figure 2. The remote station “container” for use of tele-operation.

Figure 3. Komatsu PC5500-6 Shovel.

Figure 4. The interior of the “container” with operator stations.

Figure 5. Open-pit layout with teleremote application and network access points.